Job Archives

- FluxCore 0.52, 3/32, 1/16

- Read Blueprints and understand welding symbols

- Move material using a forklift and crane according to standard operating procedure, safety regulations and practices

- Select and install proper welding wire and gas mixture

- Operate a fuel gas hand torch for heat straightening purposes

- Perform cleaning, assembly, and straightening operations as directed by Supervision

- Set-up and fine tune welding machine for proper wire speed and machine voltage

- A minimum of two years experience as a Welder

- The right candidate should pass a follicle test and Weld test

- High school diploma or equivalent

- Able to read and comprehend blue prints

- Work at heights and in confined spaces

- Able to read a tape measure, pressure gauge, level, and square

Job Features

| Job Category | Manufacturing |

- Oversee the selection and procurement of materials and equipment required for TIG welding

- Measure and align workpieces using straightedges, clamps, and calipers

- Fill ducts with water/air and submerge in water to identify pipe leakage

- Ensure compliance with established health/safety policies and regulations

- Carry out grinding and thermal cutting operations to obtain various textures and sizes for metal parts

- Oversee the set-up of TIG welding equipment

- Operate power and hand tools such as arc welders, buffing machine, and scrapers

- Maintain good working knowledge of the welding characteristics of metals such as stainless steel, aluminum, and titanium

- Read and interpret welding blueprints, schematics, and codes

- Carry out preventative maintenance and repair of piping systems and metal structures

- Ensure welding operations meet set specifications and construction requirements

- Perform TIG welding on materials such as fiberglass, iron, plastic, and copper

- Conduct radiographic and bend tests to verify the quality of weld.

- High school diploma or similar.

- A completed apprenticeship or vocational training.

- A relevant certificate from a welding association may be required.

- Excellent stamina, strength, and dexterity.

- Ability to remain calm and focused under pressure.

- Sound understanding of welding safety.

- The ability to teach would be advantageous.

- A willingness to learn and work overtime when required.

Job Features

| Job Category | Manufacturing |

- Selecting, measuring, cutting, and joining appropriate metals to specifications.

- Preparing metals and work surfaces to ensure safe and effective assemblage.

- Interpreting specifications and blueprints accurately.

- Training welding apprentices and mentoring recruits.

- Regularly cleaning and inspecting welding equipment and tools.

- Operating cranes and other machinery to transport materials to welding worksites.

- Determining correct gas ratios.

- Testing the strength of each join during and after project completion.

- Diagnosing issues and troubleshooting as required.

- Liaising with the line manager or supervisor, reporting any issues, and making suggestions for improvement.

- High school diploma or similar.

- A completed apprenticeship or vocational training.

- A relevant certificate from a welding association may be required.

- Excellent stamina, strength, and dexterity.

- Ability to remain calm and focused under pressure.

- Sound understanding of welding safety.

- The ability to teach would be advantageous.

- A willingness to learn and work overtime when required.

Job Features

| Job Category | Manufacturing |

- Helps manufacturing staff achieve company goals by communicating expectations, planning, monitoring, and evaluating job results

- Enforces company policies and guidelines

- Recruits, hires, and trains employees

- Assists workers by offering personal growth opportunities

- Implements cost-saving strategies and techniques

- Ensures that production plans are completed by a certain time

- Contacts appropriate sources for repair issues

- Counsels employees on how to achieve an optimal output or workflow

- Resolves issues and disputes between manufacturing employees

- Creates and maintains professional schedules

- Communicates with and assists other manufacturing departments as needed

- Evaluates the condition of production equipment

- Maintains a clean and safe environment for all workers

- Compiles and analyzes production records

- Previous supervisory experience

- Excellent coaching and communication skills

- Ability to track expenses and compile budget reports

- Broad knowledge of production planning processes

- Strategic planning skills

- Comfortable working in an automotive manufacturing environment

- Understanding of machine controls and instrumentation

- Able to deal with complex issues in a fast-paced setting.

Job Features

| Job Category | Manufacturing |

- Communicating with customers, making outbound calls to potential customers, and following up on leads.

- Understanding customers' needs and identifying sales opportunities.

- Answering potential customers' questions and sending additional information per email.

- Keeping up with product and service information and updates.

- Creating and maintaining a database of current and potential customers.

- Explaining and demonstrating features of products and services.

- Staying informed about competing products and services.

- Upselling products and services.

- Researching and qualifying new leads.

- Closing sales and achieving sales targets.

- High school diploma/GED.

- Previous experience in an outbound call center or a related sales position preferred.

- Proficiency in Microsoft Office and CRM software such as Salesforce.com.

- Excellent communication skills, both verbal and written.

- Good organizational skills and the ability to multitask.

- Excellent phone and cold calling skills.

- Exceptional customer service skills.

- Strong listening and sales skills.

- Ability to achieve targets.

- Reading instructions and examining surfaces to determine the amount of work necessary.

- Prepping the product and other surfaces for painting along with ensuring the quality of the paint (no mixing)

- Paint surfaces according to instructions using a variety of methods (wet/oil paint)

- Able to be fitted for a respirator

- Moving the finished painted product

- Disposing and removing of old paint appropriately

- Completing work orders in a timely and efficient manner.

- Cleaning the painting equipment and maintaining an organized work area

- Maintaining all required paperwork, records, documentation, etc

- Requires painting experience preferably in an industrial setting

- Requires working knowledge of basic hand tools

- Requires the ability to use hand tools and power tools safely

- High school diploma or GED.

- Experience painting a variety of surface types.

- Proficiency with technical machinery.

- Physical strength to operate machinery.

- Diligence and attention to detail.

- Excellent dexterity and hand-eye coordination.

- Good organizational skill.

- Good verbal communication.

- Answer and direct phone calls

- Organize and schedule meetings and appointments

- Maintain contact lists

- Produce and distribute correspondence memos, letters, faxes and forms

- Assist in the preparation of regularly scheduled reports

- Develop and maintain a filing system

- Order office supplies

- Book travel arrangements

- Submit and reconcile expense reports

- Provide general support to visitors

- Provide information by answering questions and requests

- Generate and handle reports

- Prepare and monitor invoices

- Carry out administrative duties such as filing, typing, copying, binding, scanning etc.

- Organize travel arrangements for senior managers

- Book conference calls, rooms, taxis, couriers, hotels etc.

- Maintain computer and manual filing systems

- Handle sensitive information in a confidential manner

- Reply to email, telephone or face to face enquiries

- Develop and update administrative systems to make them more efficient

- Resolve administrative problems

- Receive, sort and distribute the mail

- Answer telephone calls and pass them on

- Manage staff appointments

- Maintain up-to-date employee holiday records

- Coordinate repairs to office equipment

- Greet and assist visitors to the office

- Photocopy and print out documents on behalf of other colleagues

- High school diploma or equivalent. Bachelor's degree preferred.

- 4+ years supporting multiple Executive leaders

- Working knowledge of Microsoft Office Outlook, Calendar, PowerPoint, Word, and Excel. Knowledge of SharePoint and other applications a plus.

- Excellent written and verbal communication

- Excellent interpersonal skills

- Ability to apply good judgment in making independent decisions and coordinating information

- Ability to handle and manage multiple priorities and adapt to rapidly changing needs and priorities

- Organizational

- Problem solving

- Repairs and maintains school buses and school bus equipment.

- Test drives repaired equipment.

- Oils and greases vehicles; changes filters.

- Basic computer skills in order to navigate in ISIS for diagnostics

- Knowledge of basic engine and driveline

- Knowledge of basic electrical

- Knowledge of cab and suspension

- Trailer preventative maintenance work

- Knowledge of air, hydraulic, and full power brake systems

- Knowledgeable of medium and heavy duty truck product

- Inspection and lubrication

- Cab, frame front axle, steering gear & springs

- Brake system, air and hydraulic

- Notifies supervisor of potentially dangerous equipment and corrective action taken.

- Performs all other duties as assigned.

- Be at least 18 years of age

- Have a valid driver’s license

- Have or be able to obtain a CDL license

- Subject to a background check and drug screen

- Possess a combination of education and technical experience including a minimum of 3 years diesel service and fleet experience

- ASE Diesel Certifications Strongly Preferred (Must be able/willing to obtain)

- High Value on Master Level Diesel Techs

- Ability to work in a fast-paced, high-speed environment, follow standardized work and adhere to safe work practices in a continuous improvement environment

- Experience in a manufacturing environment is a plus

- Perform necessary pre-operation activities to ensure proper equipment startup and operation on multiple pieces of equipment

- Operate/monitor multiple pieces of equipment during operation to ensure quality production and minimal unplanned stops

- Communicate with team members and support teams to ensure continuous production of the correct product at high quality levels with minimal wasted time and materials

- Housekeeping and sanitation

- Assist in the progression of training and planned development of all machinists.

- Perform other duties as assigned.

- Experience as a Machine Operator

- Knowledge of Production Procedures

- Ability to Read Blueprints, Schematics and Manuals

- Analytical Skills

- Attention to Detail

- Teamwork

- Physical Stamina and Strength

- Handle Heavy Equipment

- Work Independently

- Multitask

Job Features

| Job Category | Manufacturing |

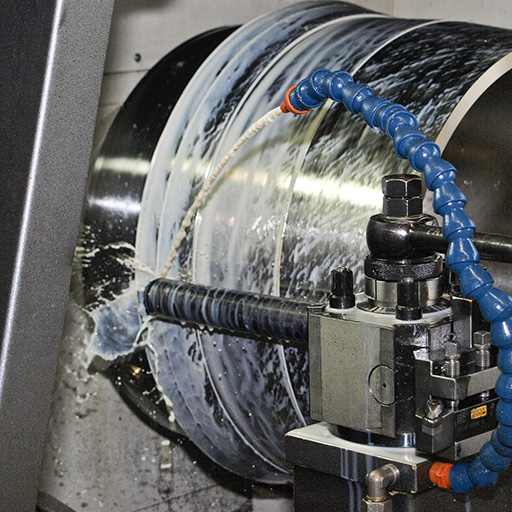

- Setup CNC turning centers for production turning.

- Troubleshoot and optimize new production programs to ensure efficient overall production.

- Document new programs and processes to ensure setups can be duplicated and overall production time is optimized.

- Oversee the quality of parts produced in the machining cell.

- To share expertise and knowledge throughout the machine shop and be a focal point for advice on machining operations

- To use skills to protect against potential damage to all machines and in particular to take overall ownership of the machine cell.

- To be proactively aware of work load and plan tooling requirements for future jobs ensuring minimum downtime.

- To make most efficient use of machinery and equipment, including the use of proper feeds and speeds.

- Inspect and deburr parts to ensure they meet blueprint specifications using proper measuring instruments.

- Produce jigs and fixtures that improve productivity.

- Implement daily and weekly maintenance programs on machine shop equipment

- Follow all safety policies and procedures.

- Assist in the progression of training and planned development of all machinists.

- Setup machines on a flexible basis to ensure optimum output throughout the shop.

- Perform other duties as assigned.

- Must have a basic understanding of CNC machining work and tool offsets.

- Must be able to identify critical blueprint dimensions and instruct workers how to inspect and check these critical dimensions.

- Ability to work on a wide variety of complex parts from drawings.

- Ability to change and adapt work behaviors based on a constantly changing production schedule.

- Must have basic computer skills including Microsoft Word, Excel, and Windows.

- Must have basic understanding of ISO 9001 and quality principles.

- Must be dependable and detailed oriented.

Job Features

| Job Category | Manufacturing |

- Set up and operate CNC Mill(s) to perform various machine functions such as; milling, turning, boring, recessing, and occasional profiling or contouring of metallic and nonmetallic work-pieces.

- Set-up, create, check programs and operate automatic numerically controlled machine tools.

- First piece and in process inspections of parts produced.

- Work from operational data to define tooling, fixturing, and machine arrangements.

- Recommend tooling arrangements, fixtures, and operational sequences, etc.

- Use a variety of precision measuring instruments.

- General knowledge of machine shop practices and techniques, machine operation and tooling.

- Must have a basic understanding and knowledge of injection molding process, equipment and materials. The addition of other molding processes is helpful.

- Completion of a state indentured tool and die apprenticeship, CNC Machinist apprenticeship or accrued experience.

- Must be able to read and understand blueprints, specifications and routings.

- Ability to add, subtract, multiply, and divide in all units of measure, using whole numbers, common fractions, and decimals.

- Minimum of 2 years experience.

- High School diploma or GED.

- Positive attitude

Job Features

| Job Category | Manufacturing |

We are looking for an energetic Warehouse Worker to receive and dispatch merchandise to and from our warehouse. The Warehouse Worker will load and unload outgoing and incoming delivery vehicles. You will select products from the warehouse, load and secure goods to pallets, move inventory to delivery area, and load merchandise. You will unload stock from delivery vehicles, and transport to and store in designated warehouse positions. You will keep your work environment clean and tidy at all times, and comply with all relevant safety rules, regulations, policies and procedures.

To ensure success you need the ability to follow instructions and operate in an orderly manner. Preferred applicants are hard-working, focused and have outstanding problem-solving skills.

Job Responsibilities:

- Ensuring cleanliness, tidiness and safety of work environment.

- Loading and unloading delivery vehicles.

- Accepting delivery of inventory.

- Counting and confirming inventory.

- Inspecting inventory for damage and faults.

- Communicating errors to relevant parties.

- Marking and labeling stock.

- Storing inventory in accessible manner.

- Loading and wrapping stock on pallets.

- Building loads with forklift and electronic pallet jack.

Job requirements:

- 18 years of age or older.

- Work experience as general laborer, preferably in warehouse.

- Ability to operate forklift proficiently.

- Completion of background investigation and drug screening.

- Strong people skills.

- Good moral character.

- Physically strong, agile and dexterous, and undeterred by heights and adverse climatic conditions.

- Positive work history and ability to maintain solid attendance.

- Available to work extended hours.

Pay Rate: $10-18 per hour

Days/Hours (shift): Monday- Friday. 1st shift (8:00am to 5:00pm), 2nd (4:30pm to 3:00am)

- Loading, unloading, shipping and receiving warehouse items.

- Transporting materials to different locations within the facility.

- Optimizing loads to ensure operational efficiency.

- Securing loads to machine before transportation.

- Inspecting for damages to vehicles.

- Scheduling vehicles for maintenance and repairs.

- Operating and managing technical equipment.

- Managing inventory by utilizing RF scanning equipment.

- Picking and wrapping orders for shipment.

- Identifying workplace safety hazards.

- Adhering to safety management standards.

- Adhering to production schedules.

- High school diploma or GED.

- Valid fork-lifting certificate.

- Excellent hand-eye coordination.

- Proficiency operating technical machinery and RF scanners.

- Good physical condition.

- Mathematical aptitude.

- Good organizational skills.

- Attention to detail.

- Good written and verbal communication.

Job Features

| Job Category | Manufacturing |

- Designing, maintaining, implementing, or improving electrical instruments, facilities, components, equipment products, or systems for industrial, commercial or domestic purposes.

- Performing a wide range of engineering tasks by operating computer-assisted design or engineering software and equipment.

- Conferring with customers, engineers, and others to discuss existing or potential engineering products or projects.

- Ensuring that installation and operations conform to standards and customer requirements by preparing electrical systems specifications, technical drawings or topographical maps.

- Establishing construction, manufacturing or installation standards or specifications by performing a wide range of detailed calculations.

- Ensuring compliance with specifications, codes, or customer requirements by directing or coordinating installation, manufacturing, construction, maintenance, documentation, support or testing activities.

- Writing reports and compiling data regarding existing and potential electrical engineering projects and studies.

- Preparing specifications for purchases of electrical equipment and materials.

- Supervising or training project team members.

- Estimating material, labor, or construction costs for budget preparation.

- Maintaining electrical equipment.

- Working with a variety of technicians.

- Bachelor degree in electrical engineering degree from an accredited school.

- Licensed as a professional engineer.

- Experience in using or a desire to learn required software.

- Knowledge of applicable codes related to electronic engineering.

- Proficient in design and calculation software.

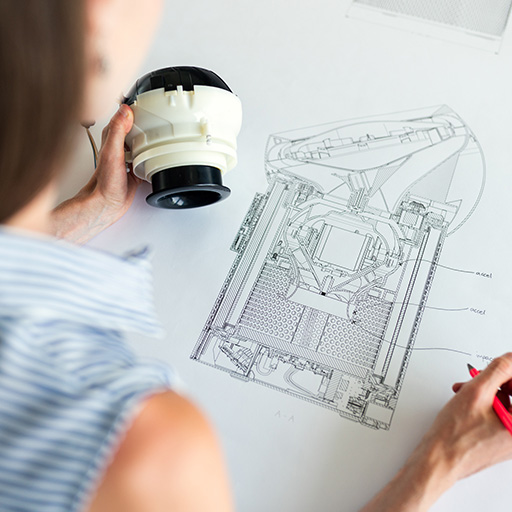

We are currently seeking an experienced and highly-skilled Mechanical Engineer. You will collaborate with a team of engineers, architects, and designers to develop more efficient manufacturing machinery that utilizes less energy without sacrificing performance.

Job Responsibilities:

- Create, refine, and detail 2D and 3D CAD models and prepare drawings using SolidWorks.

- Analyze and detail tolerances for interference and stack – up in production situations.

- Maintain ECR/ECN and revision control documentation.

- Create and detail one-time modifications or customization to existing products.

- Communicate with internal customers to understand requirements.

- Communicate changes, special instructions and other details to the production floor.

Position requirements:

- Bachelor’ s degree in mechanical engineering, mechanical engineering technology, or a related field.

- Ability to work with customer’ s to design and develop mechanical systems and solutions for their equipment needs.

- 3+ years of experience with mechanical design or manufacturing engineering work (preferred).

- Highly proficient with Autocad software.

- Experience with mathematical computing and analysis tools knowledge such as Matlab and LabView.

- Able to create 2-D or 3-D designs to run simulations, analyze, and tests

- Monitor and analyze mechanical devices for problems.

- Develop new devices or changes to improve current equipment.

- Recommend design changes, cost reductions, warranty improvements, and manufacturing issues.

- Oversee installation of new system or machinery Perform and analyze tests to track results.

Pay Rate: $50K - 80k per year

Days/Hours (shift): Monday- Friday (8am-5pm)